Industries

Construction

From the skyscrapers that dominate a city skyline to the functional single-story warehouses that support our economy, hollow structural sections (HSS) have become a preferred material for non-residential construction professionals throughout the design and build process. Architects adore the visions they are able to create using architecturally exposed structural sections (AESS). Engineers have learned the value they can provide via the high strength-to-weight ratio of HSS with proper member and connection design. And fabricators and construction professionals have realized the benefits they can provide building owners when using HSS.

Availability and reliability are two must-haves when sourcing HSS or structural pipe for your next project. We take those concerns to heart when housing our stock inventory and building flexibility into our rolling schedules. Because a broad range of shapes, sizes and thicknesses (which we can also boast, by the way) only benefits you when you can get product to the fabricator or job site where or when you want it. We’ve built our reputation on it: A dedication to responsiveness and customer service.

Farm + Agriculture

When your customers are in the fields from sun up to sun down, they trust your equipment to work just as hard as they do. In turn, you need to trust us at Searing to be just as dependable. Our pledge is to never let you – or our nation’s farmers – down in any way.

Our structural steel is durable enough for the toughest equipment demands, even in applications where tolerances and edge requirements are at their tightest. The superior strength-to-weight ratio of hollow tubes often outperforms bar and plate, especially in mobile applications where fuel economy is a factor. At the end of the day – especially a day spent on the farm – your reputation lies within your equipment’s performance. We believe ours does too.

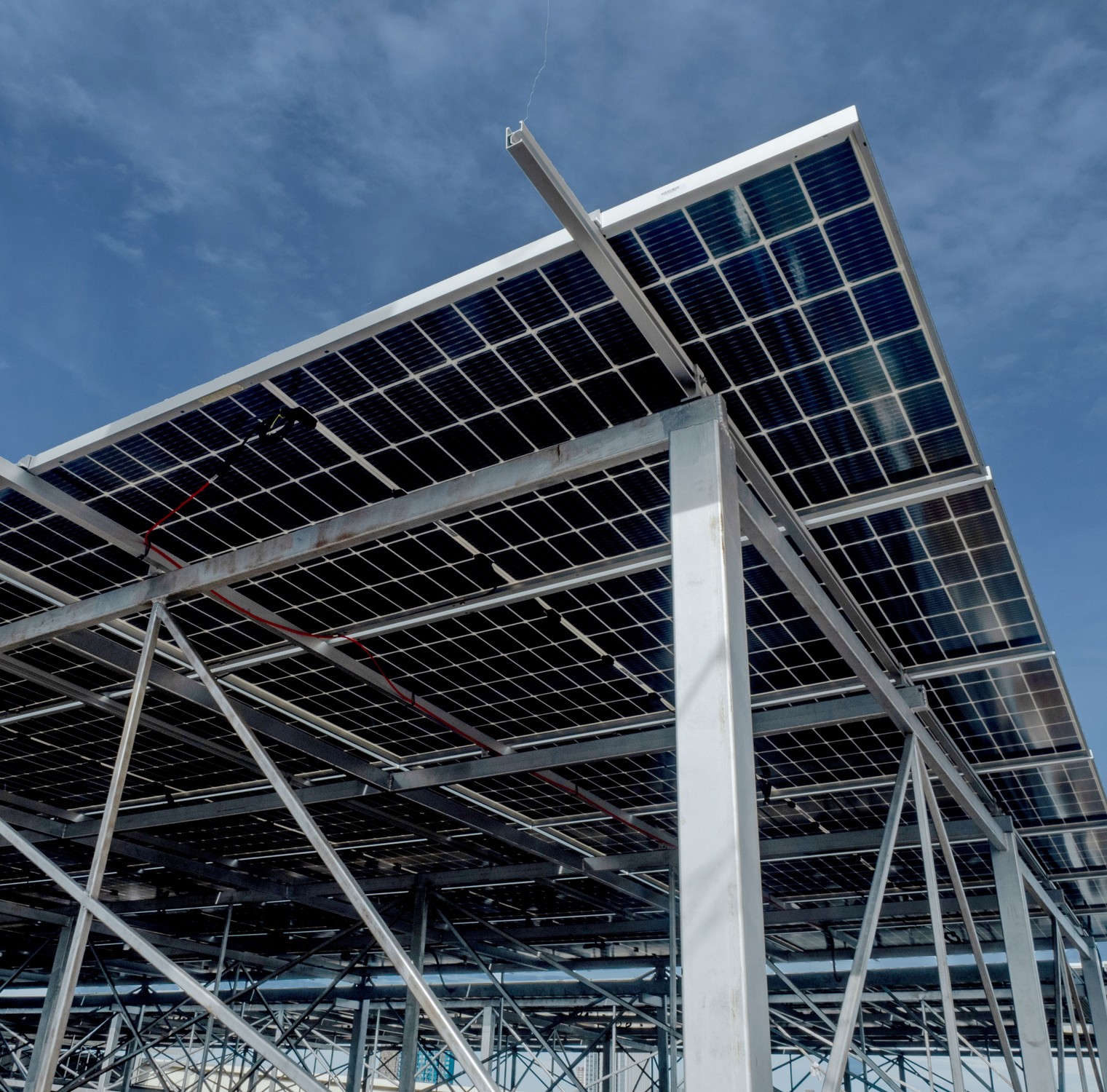

Solar

In 2021, 39% of all new electricity generation capacity in the country came from solar. Tomorrow? The sky’s the limit. We are proud to be part of the movement that supports solar’s growth as we seek innovations to lessen our dependence on fossil fuels, especially in the states we serve throughout the West, Plains and Midwest.

Our solar customers have some of the most demanding and exacting standards, not only for our tubes themselves but also for our value-added services. We enjoy nothing more than turning those challenges into possibilities. The strength and rigidity of steel makes it a clear choice over other materials for the structural and racking components of solar projects. And since steel is the most recycled material in North America, it only makes sense to use the most environmentally conscious material in applications seeking to help improve our environment. Working by your side, we believe there are no limits to the future of the solar industry.

Exercise Equipment

One out of every five Americans pay for a gym membership and some studies suggest that up to half of our homes have at least on piece of exercise equipment. The health and fitness craze that started in the 1980’s stopped being a fad long ago and is now simply a lifestyle. We’ve been providing excellent solutions for our fitness equipment customers for just as long.

Steel tube’s aesthetics and durability make it the go-to solution for a wide variety of equipment components where performance must be matched by smooth, clean lines. Our extensive size and gauge options along with our ability to meet tight tolerances and edge requirements make us your go-to partner for applications others can’t tackle. Developing the best solutions for our exercise equipment customers to keep you strong is one of our most favorite “workouts”.

Racking

One of the opportunities of the eCommerce boom is the shift from retail space needs to a boom in warehouse space. A survey conducted at the end of 2015 put vacancy at a 15-year low for Class A warehouse space across the country. Lining those warehouses? Racking systems made from steel tube, of course.

Being able to provide maximum strength in large and small diameters as well as thick and thin gauges is one of the most common attributes our racking customers cite for their reliance on tube. Our product consistency and in-line coating capabilities are just two of the reasons they prefer Searing. Finish with our responsiveness and dedication to customer service and you’ll understand why some of our longest-lasting customer relationships are with racking manufacturers.

Fencing

Sometimes what you want most from your supplier is nothing. No hiccups. No hassles. No defects or surface imperfections. No missed deadlines or late shipments. Meeting those criteria for the fencing industry is actually a pretty big something for our team at Searing.

Our durable steel tube and pipe are manufactured to withstand the harsh conditions that come with a lifetime of outdoor use while maintaining function and surface quality. Our in-line coating and cut-to-length services allow us to provide value-added components to save you time as well as money by removing extra steps in your production process. Some of our oldest and most trusted partnerships are with leaders in the fencing industry.

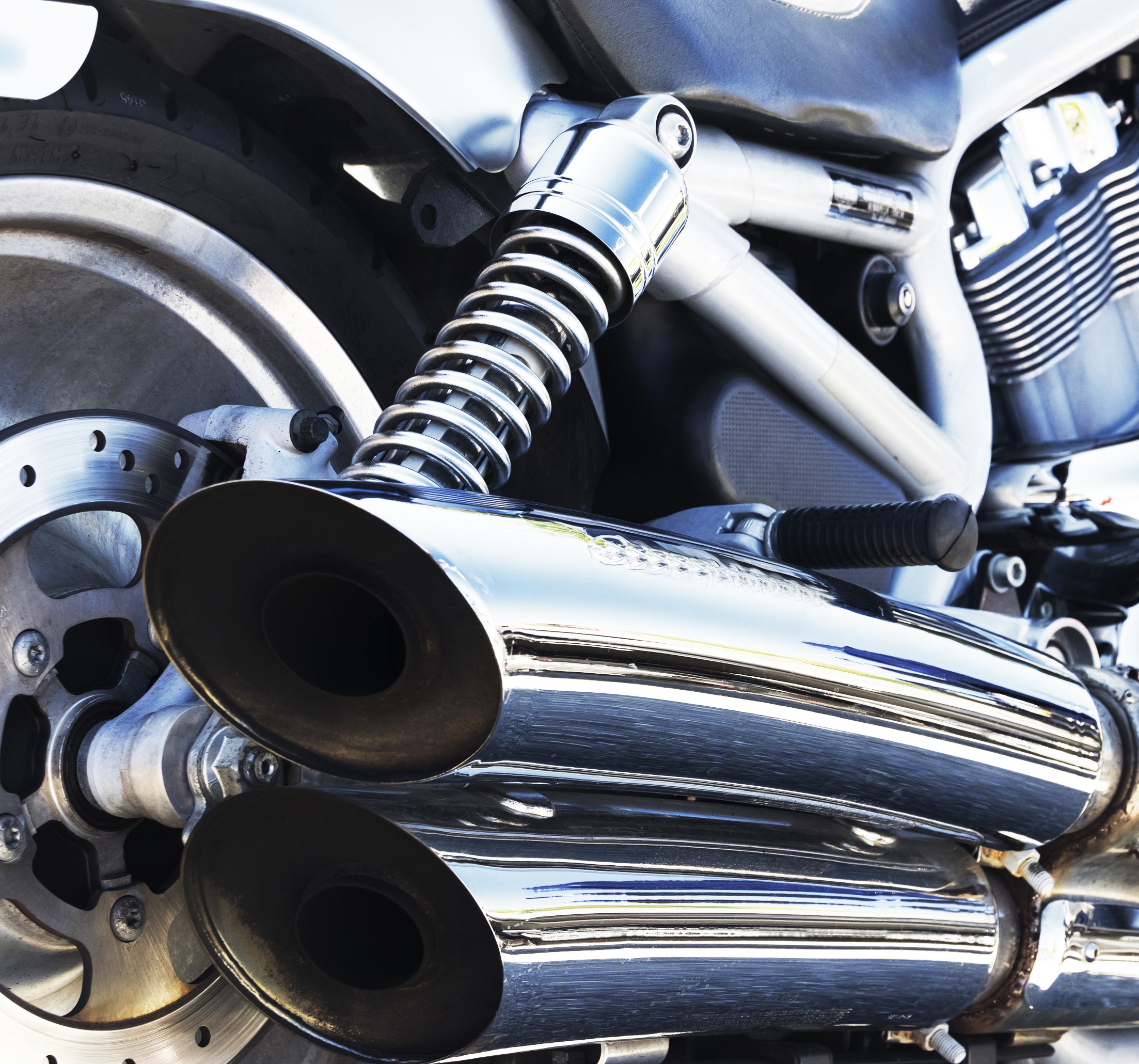

Automotive

The automotive industry is well-known for their quality and timeliness demands. The pressure to deliver best-in-class product, day-in-and-day-out, to feed a just-in-time manufacturing process can be intense. We prefer to think of it as the driver for the adrenaline rush that keeps us revved up to provide only the best tube for your application.

For any vehicle or equipment that moves and is dependent on fossil fuel, lightweighting is a priority. Hollow steel tube can provide significant savings on weight over bar or plate without compromising strength. For exposed applications, clean lines and smooth finishes add beauty to the brawn of our wide range of mechanical and structural products. Add to these features the traceability and recyclability that steel provides and it becomes clear why steel – and Searing – are here to keep you moving.

Furniture

The North American furniture manufacturing industry looks vastly different today than it did over thirty years ago when we opened our doors at Searing. Many of our first furniture companies have consolidated or moved production off-shore to stay competitive in a market now flooded with lower-cost and lower-quality products. But those who have remained – those who have carved out a niche – are the very customers we do our very best to support.

That support, of course, starts with our wide range of products that provide an array of sizes, thicknesses and finishes to help keep your products differentiated. But products and services are simply the baseline. Our true value comes to play when we are by your side, identifying solutions to some of your toughest challenges, be them logistical, product engineering or timing. We know steel. You know your biggest challenges. Together we develop solutions.