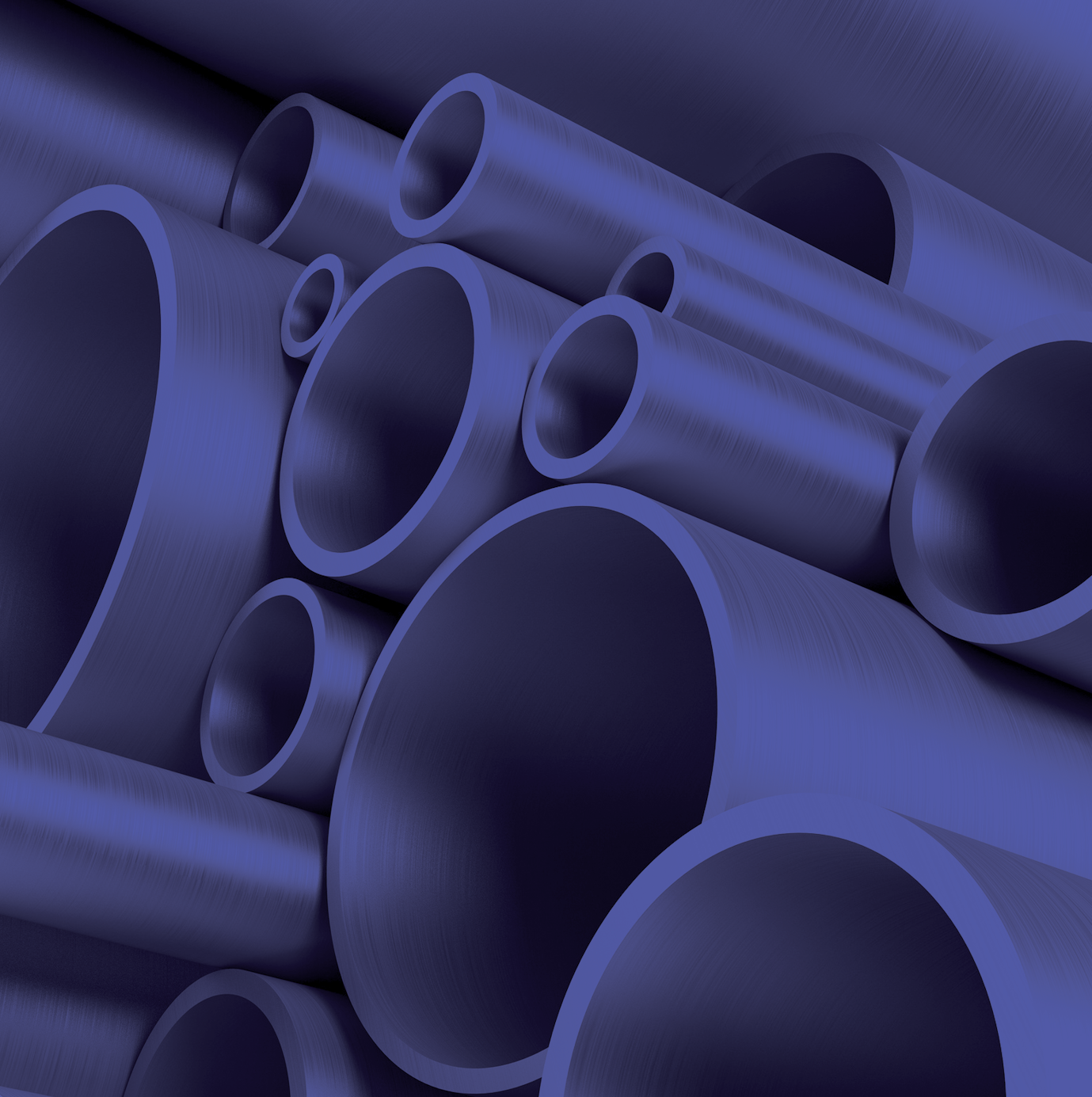

A500 B/C and A1085 Structural Tubing

Structural Tubing or Hollow Structural Sections (HSS) are high-strength welded carbon steel tube used as structural members for construction applications and a variety of manufactured products. We produce round, square and rectangular shapes to meet both A500 B/C and A1085 ASTM specifications. We then go a step further to exceed your expectations for customer service and responsiveness.

max pipe sizes offered below

up to 60' long for square & rectangle

Round

Rectangle

Square

Structural Pipe

Benefits of Structural Tubing/Hollow Structural Sections (HSS)

Strength

HSS has a high strength-to-weight ratio, excellent compression support characteristics and excellent torsional resistance.

Uniformity

HSS provides uniformity of size, shape, strength and tolerances that make its use totally predictable, especially important for demanding OEM applications.

Resistant/Consistent

HSS is fire resistant and does not warp, twist, split, swell or shrink. It resists dry rot and mildew.

Ease of Fabrication

HSS can be readily bent, formed, punched and drilled. Improvements in connection design for fastening HSS to itself or other structural materials are improving the ease of fabrication in the field as well.

Appearance & Sustainability

HSS offers preferred visual opportunities for exposed applications like AESS in construction and is made from steel, one of the world’s most recyclable and recycled materials.

Cost Effectiveness

Due to its higher strength ratio, especially in A1085, HSS is cost competitive with other structural materials. With improved connection and fastening methods, it often enjoys a cost advantage.

Built for Strength. Sized for Precision. Engineered for You.

Beyond our already extensive size range, we also run 17+ metric sizes and high-yield grade 70, 80, and 100 material. That means even more ways to get the perfect fit—whether you need added strength, unique dimensions, or both. And with production in both our California and Wyoming facilities, we’ve got the flexibility to make it happen.